Our innovative products

Cube Inline+

The modular Soldering System for highest efficiency

The intelligent modular system, flexible for every kind of customer requirements. The best possible construction of all components of the system ensures a maintenance-friendly accessibility.

CUBE.460

The system for automation in the manual soldering area

The new CUBE.460 entry-level soldering system is designed as a production cell for small and medium batch sizes. The simplified graphical programming gives you a quick entry into selective soldering technology.

ELS 3.3 Inline

Multi-axis soldering systems for flexible production with a high level of product mix

These soldering systems enable virtually all manual soldering applications to be automated. The soldering quality is on a par with that of forming gas mass soldering systems.

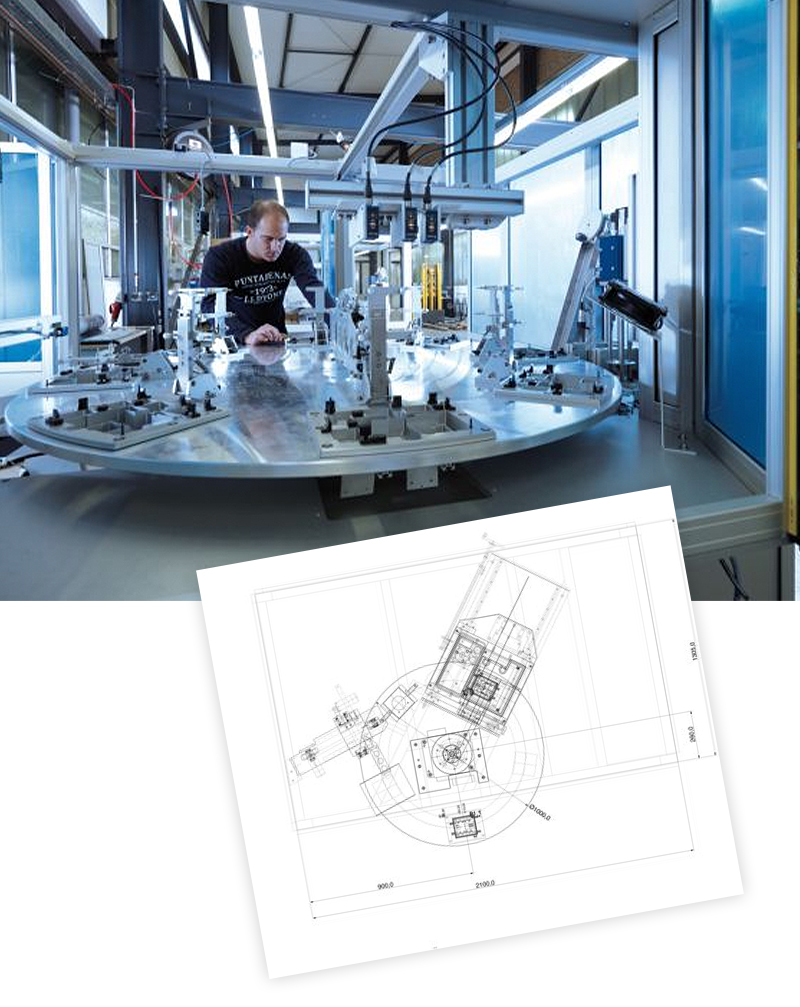

Individual special solutions

We are a reliable partner when it comes to technical production challenges.

INERTEC's specialities are design and realisation of customer-specific solutions. So all the key elements as well as the independent competence within the company are offered and therefore ideally adapted to the individual customer project.

The customer profits from combining all the components into one whole system, the supplied process and application know-how as well as the use of state-of-the-art technologies. INERTEC places a particular focus on the soldering process and its optimisation. The package ranges from the technical consultation and engineering through to the programming, commissioning and process supervision. An example of this is the design of a rotary table soldering system in which additional processes can be integrated. The company can also retrofit existing systems e.g. to adopt double-crucible technology.

If the standard doesn´t quite work, we will also gladly compile an individual concept for you, even in the case of difficult framework conditions – just give us a call and we can discuss it.