Cube Inline+ – The modular Soldering System for highest efficiency

The intelligent modular system, flexible for every kind of customer requirements. The best possible construction of all components of the system ensures a maintenance-friendly accessibility.

Clearly structured control

The simple, graphical programming allows a quick entry into the selective soldering. At the same time, the facility provides professional functions, such as process monitoring, DC-servomotors with bus connection.

Precise flux control

The drop jet fluxer is the perfect solution for flux application. Depending on the cycle time requirement, the system can be equipped with multiple spray heads. Optical monitoring of flux deposition via a light beam is standard on all INERTEC selective soldering systems, as an option we can also offer a flux flow monitoring system that will accurately measure the volume of flux being applied to each board.

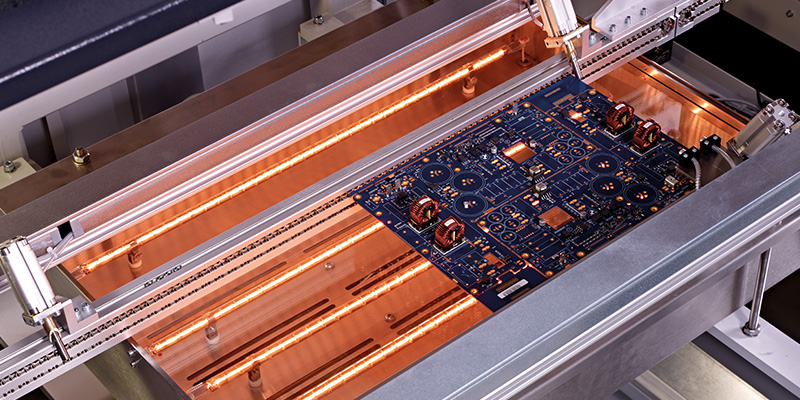

Effective Preheater

Depending on the system specification, the number of preheating modules as well as the preheating type can be selected as desired. The quartz preheating - which is the standard - provides efficient preheating with low energy consumption. The PCB temperature can be controlled via an optional pyrometer and the values transferred in BDE data.

Robust Pin-Chain Conveyor

The segmented conveyor in the system is equipped with a pin chain. The workpiece carrier or the PCB is placed precisely at the individual process positions through a stopper system. The system can be ordered with an automatic conveyor width adjustment as an option.

Process control & monitoring

Perfect process control is ensured by options such as a process camera, electronic monitoring of the soldering wave height, position correction by fiducial detection and bending of the PCB by a warpage control sensor.

Quick solder exchange

A quick change-over of the solder pot to enable the use of different solders is possible through a special trolley.

Changeable solder nozzles

The advanced design of the nozzles allows a quick exchange. If products with a different nozzle size have to be soldered, the insert of the nozzle is simply changed to the appropriate nozzle diameter.

ActiveFlow soldering module

ActiveFlow allows a high energy transfer between the smallest component clearances for PCB up to dimensions of 400 x 400 mm. Through the construction of the system, short cycle times of 30 seconds aren't a challenge for INERTEC.

From the basic design to the production line

The INERTEC CUBE Inline+ modular system offers a modular system with all the required process stages according to customer specification.

The clever design of the modules makes retrofitting modules at a later date possible and of course back again. As required.

Versatile system expansions are possible

Whether the CUBE Inline+ is used as a base system or with one of the many options, with the CUBE Inline+ you are prepared for all challenges. Here you can find all possible kombinations.

Intuitive control software

The control for the CUBE Inline+ is based on a BECKHOFF PLC. It is modular, so retrofits are possible and easily implemented at the customers site.

For programming, INERTEC uses a graphical interface via the convenient offline software or online programming via the built-in camera. Software modules, such as PCB-warpage-correction or the optional Fiducial module, detect and correct the circuit board position during the soldering process.

Industry 4.0 – The control offers all possibilities of data acquisition via XML tickets, via TCPIP, as an ASCII file of an SQL database or an ITAC connection. During the process, statistics modules capture all relevant PCB data by the DMX code or program name. A line recorder function allows the analog measured values (such as solder temperature or nitrogen temperature) to be recorded. Barcode integration, automatic time functions, integrated service messages, as well as online access are standard functions and already included in the software.

Technical Configurations

Simply download our brochure on the Cube Inline+ here.